Component Repair

Optomec’s LENS systems provide a production ready repair platform that delivers economic and functional benefits in terms of:

- Lower per-part repair costs

- Ability to repair heat sensitive components

- Reduced inventory requirements

- Longer service life

- Quick turnaround for rapid return to service

Key to its benefits, LENS is a highly targeted metal deposition technology that produces a very fine weld bead, exposing the component to far less heat than conventional methods. The resulting “heat affected zone” with LENS is smaller and more controlled so that the repair process does not damage the underlying part. And, since a LENS deposit is much finer and more precise than welding techniques, far less finishing work is required. Finally, with exceptional material and interface characteristics that are often superior to those of the native material, a LENS repair can potentially reduce future maintenance requirements.

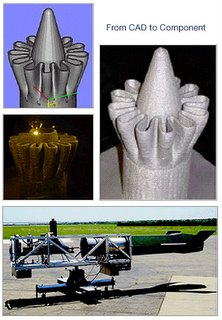

Component Fabrication

High performance components are often made from specialty materials like titanium that are time consuming and expensive to produce using subtractive methods.

In extreme cases, the Aerospace industry quotes “buy-to-fly” ratios for machined parts that can be as high as 15:1, highlighting the inefficiency and waste that is inherent in traditional methods.

In extreme cases, the Aerospace industry quotes “buy-to-fly” ratios for machined parts that can be as high as 15:1, highlighting the inefficiency and waste that is inherent in traditional methods.LENS is an ideal alternative for producing such components because additive manufacturing provides for lower processing costs, faster turnaround, and significantly reduced material waste. The superior material properties with LENS serve to extend component life, reducing life cycle costs. The process also improves design flexibility by allowing novel geometries, structures and material gradients.

In addition to its ability to produce a complete part, LENS integrates well with other processes to create unique hybrid manufacturing solutions by adding high-resolution features to large forged or cast components, or by adding layers of wear-resistant materials as a protective surface.

US Army – Anniston Army Depot, Anniston, Alabama

The US Military’s maintenance operations alone support more than 500 ships, 16,000 aircraft, 50,000 ground vehicles, and other military assets at a cost of greater than $40 billion annually. The military repair applications for LENS cover aircraft, as well as land and sea based systems. In one example, the US Army’s Anniston Army Depot (ANAD) has been using its LENS system to repair a number of Honeywell gas turbine engine components for the M1 Abrams Tank. The Tank-Automotive & Armament Command (TACOM) has approved the LENS process, and ANAD estimates annual savings of up to $5 million using LENS to repair just a handful of approved components. With the success of this first system installation, ANAD has recently ordered its second LENS machine.

The US Army has also selected LENS for its Mobile Parts Hospital, which will provide a real-time battlefield repair capability that reduces the need to deploy large spare parts inventories and helps minimize down time of mission critical assets. The US Navy is implementing its first LENS system at the Naval Undersea Warfare Center (NUWC).

No comments:

Post a Comment